First-Visit Fix as an Service Level Objective (SLO): Cut Return Trips with SKUduction

Every service call should be resolved in one visit. Return trips waste technician time, burn fuel, hurt margins, and frustrate customers. SKUduction helps techs carry what they need.

Executive summary:

Return trips drain margin and patience. Make “first-visit fix” a service-level objective (SLO), reduce variant sprawl with SKUduction coverage sets, and align truck stock with a simple, model-free identification workflow. Result: fewer callbacks, happier customers, better utilization.

The business cost of a return trip

Lost technician time: 60–120 minutes of drive/park/re-tear-down that could’ve been another paid job.

Hard costs: Fuel, shipping, and vehicle wear on the second dispatch.

Soft costs: Customer inconvenience, reschedules, and slower cash collection.

Why return trips happen

Identification gaps at the door: Tags are missing, unreadable, or don’t match what’s installed.

Variant sprawl: Dozens of near-duplicates create hesitation and wrong picks.

Truck-stock gaps: You’ve got “close, but not quite,” which forces a reorder and a revisit.

Quick ROI math (plug your numbers)

Return-trip cost per call ≈ (minutes lost ÷ 60 × billable rate) + fuel/vehicle.

Avoidable second trips per week × cost = budget for coverage sets—with margin left over.

SKUduction in one line

Fewer SKUs, broader coverage, faster decisions.

SKUduction compresses overlapping parts into coverage sets — small, engineered assortments that handle most field cases so techs can diagnose and complete in one visit.

Coverage sets (the heart of the method)

A coverage set is the smallest group of parts that will let a tech repair the majority of failures they actually see in their territory.

Category-based: Ignition, pumps/valves, radiant elements, etc.

Territory-tuned: Built from local sales/repair history so you’re carrying what breaks where you work.

Tiered:

Core: Covers ~70–80% of likely calls. Lives on every truck.

Extended: Adds ~10–20% more coverage for high-volume routes.

Rare: Kept at the shop or cross-dock for edge cases.

How you build them

Pull 12–24 months of local job logs and counter sales.

Map OEM numbers to SKUduction equivalents.

Sort by frequency; select the smallest set that hits your target coverage (e.g., 85–90%).

Assign par levels by route volume; review quarterly.

Example: Radiant elements replaced without the exact OEM

When a radiant doesn’t heat, the goal is to replace it now, not hope the exact OEM is on the truck or make a pickup.

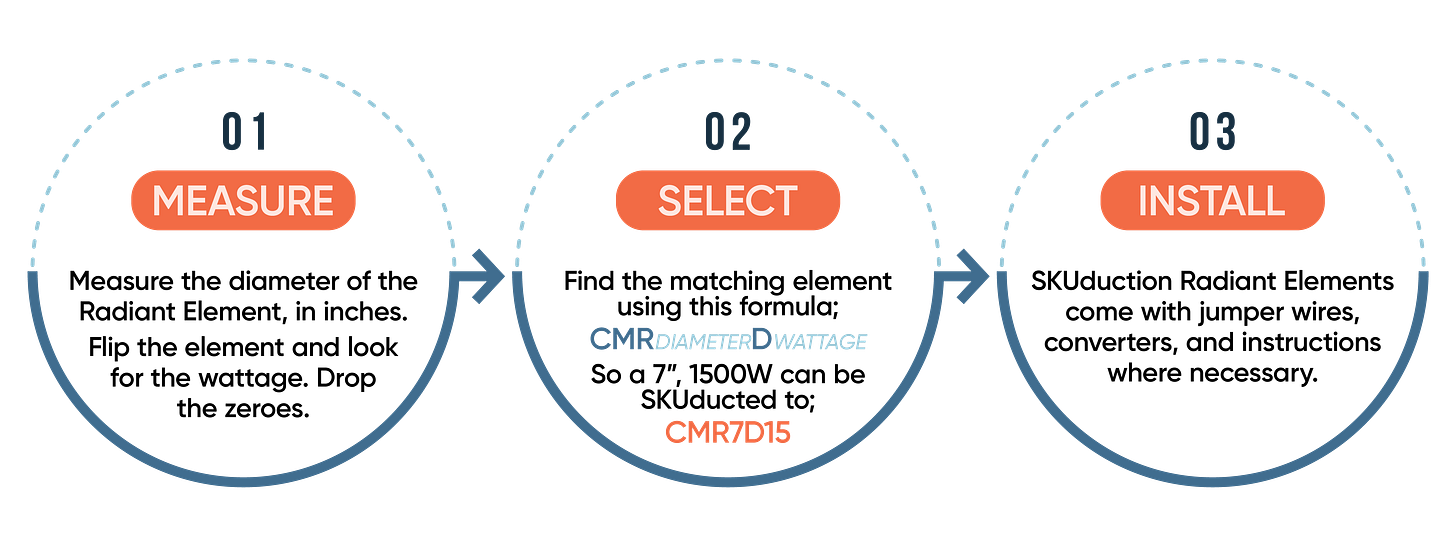

Workflow: Measure → Select → Install.

Measure diameter and confirm wattage.

Select the SKUduction element that fits that range/wattage from your coverage set (not an exact OEM clone).

Install and test.

Result: You complete the repair on site, without carrying every model-specific variant.

Turn “first-visit fix” into an SLO (Service Level Objective)

SLO: Resolve ≥ X% of calls in one visit.

Track simply: If a second trip is needed, tag one reason: ID error / missing coverage / rare part / process miss.

Tune weekly: Use the tags to adjust coverage sets and par levels—by route, not just company-wide.

Bottom line

A first-visit fix is the service promise customers remember. Coverage sets make that promise practical: fewer SKUs to carry, broader coverage on the truck, and a simple, model-free selection method that works at the door. Start with a single category, set your SLO, and tune from your own data — then repeat across the next category.

For distributors

With the ease of internet ordering, an increasing trend is for customers to purchase parts online (sometimes even from suspect sources). If you are unable to provide your customer with a replacement you may lose a sale to an online retailer.

Distributor expertise is one of the largest contributing factors to customer loyalty and purchasing in-store rather than online. Give your customers the expertise of your experience AND the availability of replacement parts by stocking SKUduction coverage sets for your region.

Make your customers measurably better

Sell by coverage set (not by catalog page): Package sets by category and territory. Label what each set covers and the quick ID method techs use at the door.

Territory subsets: Offer Core / Extended / Rare tiers to match route volume and van space.

Quarterly tuning: Review returns and second-trip tags by ZIP; rebalance sets accordingly.

10-minute counter training: Practice the phone script aligned to the tech’s method (e.g., “measure diameter/wattage → match coverage SKU”).

New offer: “Recommended Coverage Set” from your data

If a distributor can provide OEM sales history (SKU, quantity, date, ZIP or branch), we can:

Map OEM → SKUduction equivalents,

Rank by frequency, and

Deliver a recommended Core/Extended/Rare coverage set with suggested par levels by branch or route.

You get a stocking plan that directly reflects what your customers actually fix, and a clear buy list for customers who visit your store.